As custom transformer specialists, the engineers at Triad are always ready for a new challenge. Recently, we got just that when a customer came to us in need of a customized high-voltage transformer for a medical optics application. Below is the case study highlighting this exciting project.

The Challenge

After receiving a direct referral from an engineer our client knew at another company, they approached our team with a very particular challenge: Their medical optics transformer supplier was no longer viable. They needed a customized high-voltage (18 KV) transformer that would provide them with the high reliability and performance the application required — and they needed it fast.

Production for this piece would also require specialty high-precision winding, as well as a custom vacuum varnish to meet specific high-voltage requirements.

The Solution

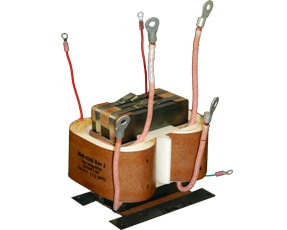

The Triad engineering team was provided with very general, vague specifications, but they realized immediately that they would need to do a complete redesign of the existing transformer. To construct the new components, we worked with two hundred and fifty nine strands of 37 AWG Litz wire, two ferrite core sets, and 24 AWG magnet wire, combined with a 100% vacuum impregnation.

Our manufacturing engineers relied on our in-house precision coil winding machines to craft a prototype that could be reliably and consistently reproduced. Although this was a very unusual and complex design, the transformers worked with the first prototype. The customer placed the sample unit in the intended oil bath (common for high voltage components), pulled a vacuum to remove all air, and energized the transformer. After verifying the expected 18kV output, they decided to “stress” the unit – they increased the voltage until it was producing 32kV. And as it was Friday, they let it run at that level over the weekend. When they returned Monday to find that it was still happily producing 32kV they said “well, if it can do that for 60 hours straight, it should be just fine”. The final part dimensions were a compact 5.50 inches in width x 3.75 inches in length x 3.50 inches in height.

And to ensure optimal quality, we performed output voltage, DC resistance, and hipot testing before sending out the part to the customer.

The Result

The client was so pleased with the transformers’ performance that they immediately placed an order for over $25,000, which we were able to deliver within their tight four-week turnaround time.

The transformers have now been in service for nearly a year with flawless performance, ensuring optimal safety and reliability in this sensitive medical optics application.